All shock absorbers need some amount of airspace to allow the hydraulic fluid to expand and move properly, however, when the air mixes with the hydraulic fluid, it can cause it to aerate (foam) and therefore lose damping effectiveness. This most commonly happens in standard hydraulic shocks.

Nitrogen gas is used to replace air within a shock absorber to help control the flow of hydraulic fluid (this is because it is not readily absorbed into the fluid like air). Various shock designs do this differently.

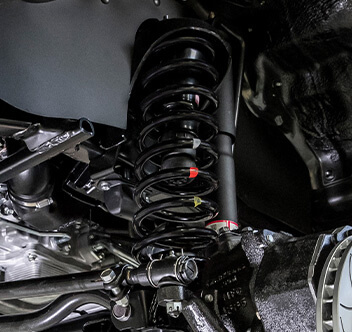

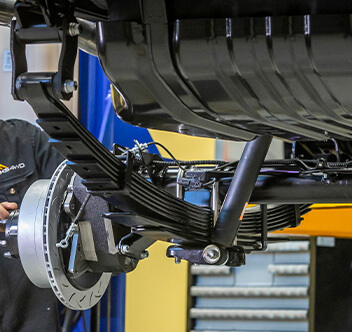

Within a twin-tube shock, the gas sits in the reserve tube to keep pressure against the fluid as it passes through the valving and prevents it from being dumped into the reserve tube.

A mono-tube shock uses a floating piston at the base of the piston bore to separate the hydraulic fluid from the gas, also preventing aeration. This design, however, reduces the travel of the piston within the shock body, affecting the overall travel of the shock.

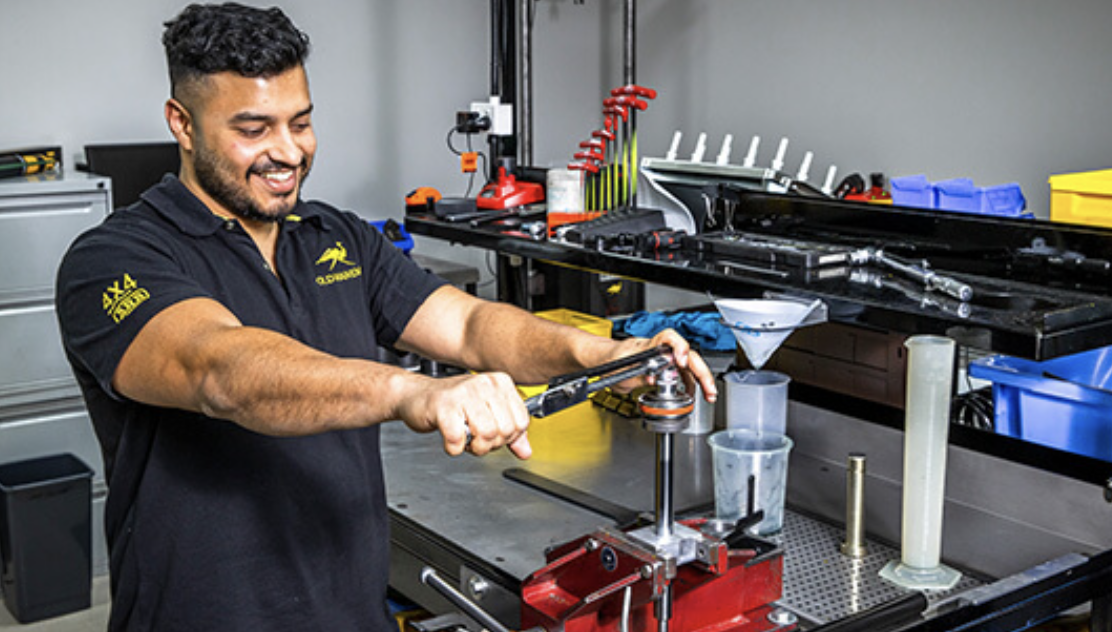

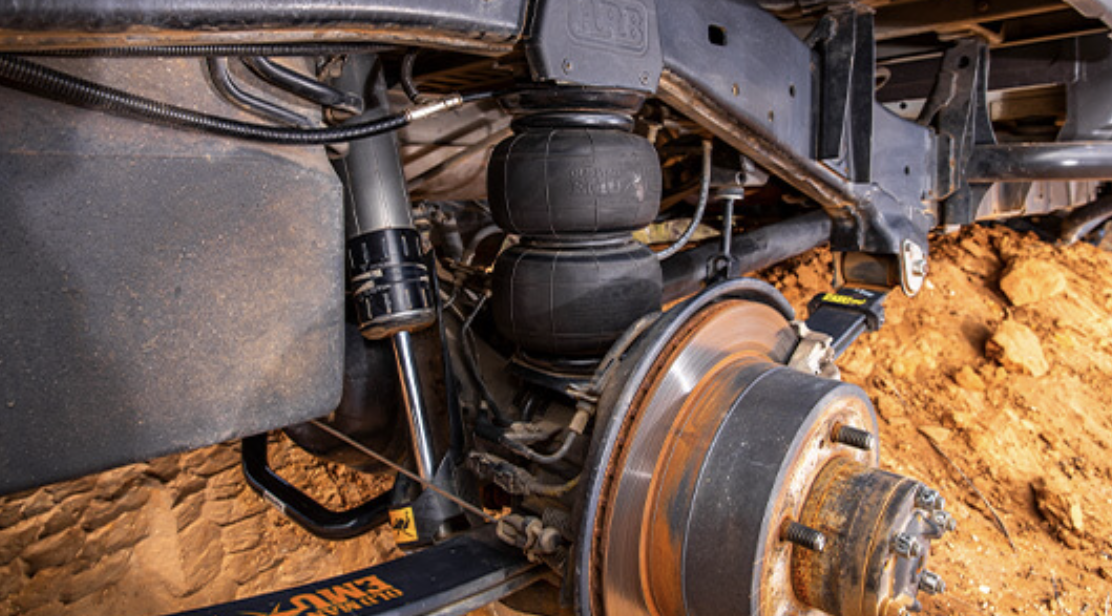

Like a mono-tube shock, the external canister in a BP-51 utilizes a floating piston to separate the hydraulic fluid and gas, however, it is contained within an external reservoir so as not to cause a restriction on the shock travel. The reservoir is large to handle the increased fluid volume in the shock and is remote mounted to aid fitting. Additionally, it can also help cool the hydraulic fluid as it is routed away from the hotter moving internal components.